Q. Kindly give our readers an introduction to your business. Please include what your business is all about, in which city you are located and if you have offices in multiple locations/ cities.

A. 1. About Dioxide Materials

Dioxide Materials Inc. is a seven-year-old startup based in Boca Raton, Florida, that expects to become a world leader in CO2 recycling to fuels and chemicals. We have already developed and patented a catalyst that allows CO2 conversion to occur at record selectivity and energy efficiency (>97% selectivity and >80% overall energy efficiency.) Lab scale devices have worked for thousands of hours with no change in performance. Under ARPA-E support, we have developed the lowest cost electrolyzers for CO2 recycling. The portfolio includes patented catalysts that halve the amount of energy needed to do CO2 recycling, and unique patented anionic membranes that allow long term performance. To date, all of the patents are owned by Dioxide Materials. Although CO2 recycling to fuels is our first application of the technology, we are confident that the technology will also find applications in long term energy storage, and inexpensive production of high value chemicals. We expect to become the go-to company for new electrolyzers and ionic membranes in these markets, eventually generating billions of dollars of annual sales.

2. Vision

Dioxide Materials’ long-term vision is to create the technology for a new chemical value chain using carbon dioxide feedstock and renewable energy (instead of oil) to obtain high value fuels and chemicals. Our technology breakthrough lowers the cost of converting carbon dioxide into C1 building blocks by a factor of three, creating the first cost-competitive route to large volume, renewable fuels and chemicals. We have made olefins directly from CO2, but the cost is higher than from natural gas. The goal is to develop a new industry where waste carbon dioxide from fermenters, power plants, and the air is used as a feedstock to produce gasoline, diesel fuel, jet fuel, and industrial chemicals —reducing the world’s dependence for imported oil, and creating thousands of U.S. jobs while significantly reducing the greenhouse gas emissions that lead to global warming.

Q. Kindly give us a brief description about yourself (it should include your brief educational or entrepreneurial background and list some of your major achievements).

A. I am Rich Masel, Founder & CEO, Dioxide Materials and a retired Professor from the University of Illinois, Urbana Champaign. Dioxide Materials is my third startup. I was also CEO of a family business that led to a successful sale. I am listed in the 2015, 2016 edition of Highly Cited, and one of only 4 US chemical engineers so listed.

Q. What inspired you to (start a new business venture) or (to make significant changes in an existing business)? How did the idea for your business come about?

A. My business started out as a result of an idea that I published in a paper and was later published in Science and recognized as being one of the most significant breakthroughs – the first electrocatalyst that can activate CO2 at over 80% energy efficiency and 99% selectivity. Our catalyst work has appeared in the journal Science, and it has been described in over 200 news articles.

The long-term goal of this technology development is to enable industry to make synthetic fuels and chemicals that are cost competitive (comparable to the current cost of conventional processes), using CO2 as a feedstock and using carbon-neutral renewable energy as an input, thus mitigating CO2 emissions from fossil fuel combustion. We have demonstrated a significantly lower overpotential, and thus higher electrical energy efficiency for electrochemically reducing CO2 than other competitive approaches, as well as demonstrating a very high chemical selectivity toward the desired product. The Dioxide Materials approach has the additional advantage that it can suppress the competing reaction of hydrogen evolution from water on a variety of cathode metals.

Thus, the value proposition of our technology against competing technologies is on the basis of the cost to make synthetic fuels and chemicals (which is directly tied to the energy efficiency and selectivity of CO2 conversion to products of interest).

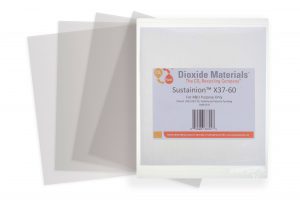

Alkaline anion exchange membranes

Q. What three pieces of advice would you give to budding entrepreneurs?

A. 1. Stay committed to your vision and don’t be afraid to fail. Sometimes it is by failing that you may learn how to become even more successful.

2. Plan, plan and plan some more- You need to plan for success and anticipate any bumps that may come up along the process, so you can work around them and continue to persevere.

3. Ensure you have funding in place and a good understating of financing.

Q. What would you say are the top three skills needed to be a successful entrepreneur?

A. 1. Strategic Planner – An entrepreneur needs to have a clear view and vision of the bigger picture and how they plan to be successful. It is important to identify long-term challenges and goals and develop a strategic plan that outlines how you are going to succeed.

2. Sales Communication – As a CEO, you are the primary spokesperson for a Company, so it is important to always maintain clear lines of communication with internal customers (employees) and external customers via email and phone, personal appearances, website and any social media sites. Your prior experience, credibility and expertise should be leveraged as a branding opportunity.

3. Finance – You need to have a decent understanding of finances, profit margins, cash flows and funding. You will need to secure your funding and focus on new ways to attract more funding or partners that can help you advance your goals. The more you know about how your money is spent, the more efficient you will be at managing expenses and growing revenues.

Anionic ionomers

Q. How many hours do you work a day on average?

A. If you ask my wife, she may tell you that I probably work too many hours to count, but I love what I do, and I am very lucky that she understands me and appreciates my vision. I retired after 32+ years of teaching on a Collegiate-level and decided that my retirement project was going to focus on developing technology that will help save the world.

Q. To what do you most attribute your success?

A. I attribute a lot of my success to an unyielding amount of persistence and a whole lot of good luck and good fortune. I always say that “God smiled” many times throughout our CO2 recycling technology development and scaling process, because so much of what happened, had never been anticipated before. The fact that we can reduce the overpotential of CO2 conversion to CO that historically has been such an energy intensive process and cost-prohibitive but is now possible because our co-catalyst technology uses 50% less energy to break the CO2 bonds.

Q. How do you go about marketing your business? What has been your most successful form of marketing?

A. Throughout the years, we have marketed our business through various vehicles including direct communication with potential customers, active participation in conferences by delivering talks or showcasing our technology at tradeshows, product launches through direct mail campaigns, website presence & SEO optimization, media interviews, published articles, sales brochures, and branding of our products and technology.

A big part of the discussion with end users, revolves around testing – and getting feedback on – the proposed value proposition and getting direct input on their needs, which can serve to further shape the value proposition as our development and technology optimization work continues.

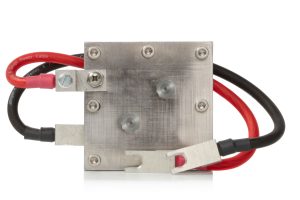

Electrolyzer components and kits

Q. Where did your organizations funding/capital come from and how did you go about getting it? How did you obtain investors for your venture?

A. Dioxide Materials is a 7-year-old startup company that has received over $16Min government funding and another $1.5M from industrial sources. Through the years, we have applied for various government grants and sought collaborative opportunities with companies that aligned with our goals.

Q. What is the best way to achieve long-term success?

A. Because our technology can enable a new energy industry, there is a lot of market development work to do. Early on, we started visiting and consulting with the players from across the supply chain and helped to coordinate their efforts to serve this new industry.

We know that energy companies are coming under increasing pressure to respond to climate change. The California Air Resources Board has mandated increasingly strict fuel carbon standards. By 2025 the standards are projected to be difficult to meet by any existing technology. There is a similar mandate for the U.S. through the Energy Independence and Security Act of 2007, although enforcement of the mandate may be changed by the current administration. Biofuels will meet some of the need for low carbon fuels, but there is insufficient arable land to meet the entire need.

Dioxide Materials expects to be a leader in providing the technology that is needed to create the zero-carbon gasoline that California and the rest of the world needs. Our process uses electrolyzers, powered by renewable energy, to convert waste CO2 and water into syngas. The syngas is then converted by a partner company’s process into gasoline (RBOB). In the short term, this process can double the amount of fuel produced by an ethanol plant. In the longer term, we expect to close the carbon cycle, so that CO2 that is emitted from automobiles is captured by vegetation or the sea, is converted back to syngas, and reused.

Q. Where you see yourself and your business in 5 – 10 years?

A. 5 years – overseeing the successful installation of our technology in the US and abroad.

10 years – consulting as needed, but mainly enjoying the “fruits of my labor” throughout my career and spending more time with my wife.

Catalyst coated electrodes for electrolyzers

Recommended Questions –

Q. How important have good employees been to your success?

A. Good employees are assets and extremely important to any organization. You should always surround yourself with smart people who will help your business grow. By working together, you can propel your business faster and attain your goals more easily.

Essential and a key asset to any successful company.

Q. How long do you stick with an idea before giving up?

A. I tend to stick to an idea until I feel that there may be other opportunities to explore. In our business, because we are developing technology, we have to be open to change and to trying new options and approaches. When we developed our Sustainion anion exchange membrane, we also tested other materials that could offer added mechanical or compression strength and support. As a result, we now offer various membranes that are useful for many applications.

Q. What motivates you?

A. I am highly motivated by trying new experiments and seeing the results. I am constantly challenging myself and my team to do better and to strive for excellence.

Q. How do you generate new ideas?

A. I like to read a lot of science journals and consult with colleagues and my team to discuss research findings and opportunities for further optimization and development.

I find that many great ideas are shared throughout the day, and if you just keep an open mind and listen carefully, you’ll hear them.

Q. How do you define success?

A. Success may be defined by many things but for me, it is knowing that I am running a successful company that attracts and gainfully employs talented individuals who are committed to my vision and share common goals in helping to develop technology that will reduce CO2 emissions that lead to greenhouse gas.

Q. How do you build a successful customer base?

A. You build a successful customer base by delivering products which offer the benefits they need. You also listen to issues and work diligently to correct any inefficiencies. You find ways to educate your customers, so they are continually apprised of other products they may need while ensuring you keep an open dialogue for continued feedback and improvement opportunities.

Q. What is your favorite aspect of being an entrepreneur?

A. My favorite aspect of being an entrepreneur is having the freedom to try new ideas and explore new opportunities. I am a very self-directed and highly motivated individual and one who loves to challenge myself and my team. I enjoy surrounding myself with smart, hardworking people who want to succeed both professionally and personally.

Q. What has been your most satisfying moment in business?

A. Collaborating with Fortune 500 Companies that share mutual goals.

Q. What do you feel is the major difference between entrepreneurs and those who work for someone else?

A. Entrepreneurs thrive on risk because they know that without risk, there’s no reward.

Employees tend to thrive on security and knowing that there’s a certain element of security in working for someone else and knowing there’s a paycheck at the end of the week.

Q. What kind of culture exists in your organization? How did you establish this tone and why did you institute this particular type of culture?

A. I try to instill a TEAM culture – although as researchers, we work independently most of the day, we meet throughout the week to discuss processes, milestones and solicit input and feedback from each other. So many of the ideas we have fostered have resulted from an open dialogue and direct team feedback. I value the fact that each of our team members can greatly contribute to our continued success.

Q. In one word, characterize your life as an entrepreneur.

A. Committed – I am highly committed to having Dioxide Materials become a world leader in CO2 recycling to fuels and chemicals.